100% Boltless shell

Actually, bolt-through-less.

There are no drilled holes or inserts through the FLUX helmet to weaken the underlying ballistic material. Polymer fasteners replace all the heavy bolts, screws and other steel mounting hardware. Fastener strikes and secondary spalling are no longer an issue. Lightweight retaining structures are bonded directly to the outer shell to allow for accessory rail and shroud removal. The end result is a safer, lighter-weight helmet.

High-strength

High tensile strength structural adhesive permanently bonds the polymer retaining structures to the outer shell. Maximum surface area between surfaces yield exceptional bond strength and has outstanding performance throughout a wide environmental range.

Modular

The suspension and retention are attached to the shell independently of any exterior fasteners. If your mission requires absolute minimum weight this unique feature allows you to strip the FLUX without needing to sacrifice ballistic or impact protection.

Removable

Thermoplastic anti-rotation inserts provide you the option to remove your accessory rail if servicing or maintenance is required. Should the total applied force to the accessory rail exceed safety limits, the fasteners will fail, allowing the rail to break away from your helmet shell preventing neck or head injury.

Wilcox L4 Shroud

Precision Engineering

The L4 represents what some would consider the "gold standard" of three hole shroud design. It has a low profile, anti-snag geometry and features an anodized 6061 insert that accepts all of your optical devices and cameras. This rock solid mount is precision manufactured by Wilcox Industries at their state of the art manufacturing facility.

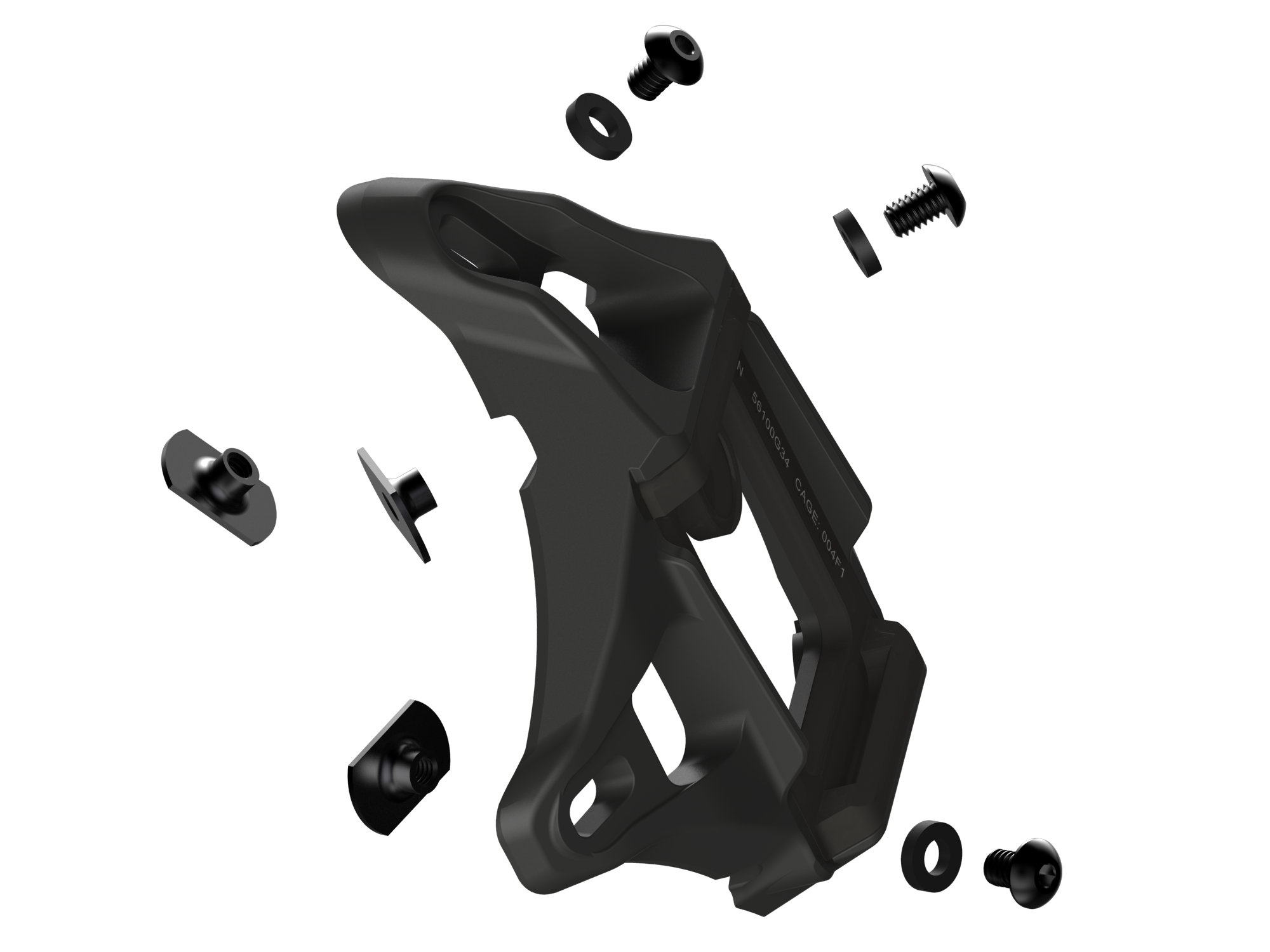

The FLUX bolt-less configuration is maintained even with the Wilcox L4 shroud. It's connected to the front retaining structure using lightweight, anodized 6061 screws backed with nylon washers, keeping the shroud stable and under proper tension. The three t-nuts represent the highest "volumetric mass density" of any fasteners contained in the FLUX helmet (basically, they're the heaviest fastener of the helmet). Their combined weight is a little more than four US one dollar bills (4.73g).